AUSTIN MARINA AND TRIUMPH TR7

Models Covered- Austin Marina

- Triumph TR7

DESCRIPTION

Rear axles are hypoid type design with center line of pinion set below centerline of ring gear. The axle shafts, pinion and differential assemblies can be service without removing axle housing from vehicle. Drive pinion bearing preload is maintained by a collapsible spacer on TR7 and by a select fit spacer and shims on Marina. All other differential adjustments are made using selected shims. Adjustment of axle shaft end play is not required.

AXLE RATIO AND IDENTIFICATION

Only one basic axle design is used on these models. To determine axle ratio, divide number of ring gear teeth by number of pinion gear teeth.

REMOVAL AND INSTALLATION

Axle Shafts and Bearings

1) With rear of vehicle raised and wheel removed, remove axle shaft nut and washer. Remove screws retaining brake drum and remove drum. Withdraw rear hub from axle shaft using suitable tool. Disconnect handbrake cable and brake pipe. Remove nuts, washers and bolts retaining brake backplate to axle housing

2) Note installed position of drip lip in relation to brake slave cylinder and remove oil catcher and backplate assembly. Remove rear hub oil seal and housing assembly. Remove oil seal from housing using suitable tool. Remove axle shaft key and place container under axle to collect oil spillage. Withdraw axle shaft from housing using suitable puller. Remove inner oil seal and press bearing from axle shaft.

3) Pack bearing with lithium based grease and dip new oil seal in light oil before reassembling. Install new oil seal with lip of seal facing inwards. Press bearing onto axle shaft until dimension from bearing to threaded end of axle shaft is to specifications. Continue assembling in reverse of disassembly using a new rear hub joint washer and using "Lactite LT 270" or equivalent on axle shaft nut.

PINION FLANGE AND SEAL

1) Raise and support vehicle. Mark propeller shaft and pinion flanges for correct realignment. Disconnect propeller shaft and remove flange nut cotter pin. On TR7, index mark flange, pinon shaft, and nut. Retain flange using suitable tool and remove nut and washer (noting number of turns to remove nut on TR7).

2) Place container under flange to collect oil spillage and remove flange and oil seal. To install, reverse removal procedure noting the following: Soak new seal in light oil for one hour before installing. Install seal with lip of seal facing inward. On TR7, align index mark on flange and shaft and tighten nut the same number of turns required to remove it. Finish tightening nut with index marks aligned.

DIFFERENTIAL CARRIER

Remove both axle shafts and mark differential pinion and propeller shaft for proper realignment on assembly. Disconnect propeller shaft. Place container under axle assembly to collect oil and remove nuts and washers retaining carrier to axle housing. Remove carrier. To reinstall, reverse removal procedure, using a new gasket and suitable gasket sealer.

OVERHAUL

Disassembly

1) With carrier removed, mount unit upright in a vise and mark bearing caps for correct reassembly. Remove bearing cap bolts, washers and caps. Assemble suitable axle stretcher (18G-131) on unit casing and stretch unit case by tightening turnbuckle three or four flats, until differential carrier can be levered out and bearing shims and caps removed. CAUTION - To avoid damaging case, do not spread any more than necessary. Maximum stretch is .008" (.20 mm). Do not pry against stretcher

2) Remove gear carrier bearing caps and mark ring gear and carrier to ensure correct replacement. Remove ring gear retaining bolts and ring gear. Drive out pinion shaft locking pin, then drive out pinion shaft. Remove pinion gears and thrust washers. Remove differential gears and thrust washers. Remove drive flange nut cotter pin and drive flange nut. Using suitable puller, remove drive flange.

3) Press out drive pinion and remove pinion bearing collapsible spacer (TR7) or shims and spacer (Marina). Using suitable press tools, remove inner bearing from pinion. Remove pinion head washer and drift out pinion outer bearing cup, bearing and seal. Drift out pinion inner bearing cup.

INSPECTION

Clean and inspect all components for wear or damage. Ring and pinion gears, differential bearings and pinion bearings must be replaced as matched sets.

REASSEMBLY AND ADJUSTMENT

Side Bearing Preload - 1) Install differential bearing cones in gear carrier using suitable tool. Install two differential gears in carrier, ensuring each thrust washer is correctly positioned. Position two pinion gears, one each side of carrier and mesh them with differential gear, turn gears and ensure two pinions rotate into mesh and align with pinion shaft hole in carrier. Install pinion shaft.

2) Press each pinion firmly into mesh with differential gears and assess required pinion thrust washer thickness required to achieve ZERO backlash. Remove pinion shaft and pinions and install thrust washers. Reinstall pinion gears and shafts with thrust washers and check that zero backlash exists. Lubricate components and install pinion shaft locking pin and secure by peening metal of differential carrier.

|

| FIG. 1 EXPLODED VIEW OF AUSTIN MARINA AND TRIUMPH TR7 DRIVE AXLE AND PROPELLER SHAFT ASSEMBLIES |

|

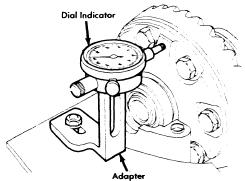

| FIG. 2 CHECKING RING GEAR RUNOUT AND TOTAL SIDE FLOAT |

3) Clean ring gear mounting and carrier face and install ring gear, tighten bolts. Assemble carrier bearing cups to bearings and position assembly in case; do not install bearing shims. Install bearing caps in correct position. Using dial indicator and suitable adapters, ensure that ring gear runout does not exceed specifications. Remove bearing caps and press differential bearing cups into bearings and move carrier assembly to axle side of case. Zero dial indicator and move carrier assembly fully in opposite direction. The indicator reading should be noted for future reference as "Total Side Float". Remove differential assembly from case.

|

| FIG. 3 CHECKING DRIVE PINION GEAR DEPTH |

Drive Pinion Depth - 1) Install inner and outer pinion bearing cups to case using suitable tools. Install pinion inner bearing to dummy pinion 18G-191 M). NOTE - Dummy pinion incorporates standard pinion head washer of .077" (1.95 mm) thickness. Oil bearing and install dummy pinion, outer bearing, tool spacer, washer and nut. Tighten nut gradually until bearing preload specification is obtained. Clean dummy pinion head and position dial indicator gauge foot of tool 18G-191 on dummy head and zero indicator.

2) Mode dial indicator over center of one differential bearing bore and note reading. Repeat for opposite bearing bore. Average these two measurements and perform the following calculation.

EXAMPLE

Average of bore measurement...................... .002" (.051 mm)

PLUS dummy pinion washer allowance....... .077" (1.956 mm)

Required size of pinion head washer........... .079" (2.007 mm)

If the etched marking on pinion face is on "N" or a dot ".", indicating normal, no change to above dimension is required. If etched marking is positive (+), reduce size of required pinion washer by amount marked. If etched marking is negative (-) increase size of required pinion washer by amount of marked. Remove dummy pinion and remove inner bearing from dummy pinion.

|

| FIG. 4 CHECKING RING GEAR-TO-DRIVE PINION GEAR BACKLASH |

Pinion Bearing Preload With Spacer and Shims - 1) Place selected pinion depth washer on on pinion and install inner bearing using suitable tools. Oil bearing and install drive pinion gear in housing. Install bearing spacer, chamferred end towards drive flange. Install shims, oil and install outer bearing. Install drive flange washer and nut. Gradually tighten nut, but do not exceed torque specification, and check preload during tightening operation.

2) While gradually tightening nut, keep checking the pinion bearing preload using an inch pound torque wrench. Tighten nut as required to obtain specified pinion bearing preload. NOTE - If pinion bearing preload torque specification is exceeded, a new collapsible spacer will be required and this procedure repeated.

|

| FIG. 5 CHECKING RING GEAR-TO DRIVE PINION "IN-OUT" MESH CLEARANCE |

Adjusting Backlash - 1) Place bearing cups on differential bearing and install carrier in case. Position dial indicator with suitable adapters on ring gear side of case. Move ring gear fully into mesh with pinion and zero indicator on rear of ring gear. Move ring gear side is butted in housing. The indicated measurement should be noted as the "In-Out" mesh clearance.

2) Perform the following calculation:

EXAMPLE

"In-Out mesh clearance (1)............................ .0025" (.63 mm)

MINUS Specified backlash........................... .005" (.13 mm)

Required ring gear side shim pack............... .020" (.50 mm)

"Total Side Float" (2)..................................... .060" (1.52 mm)

MINUS ring gear side shim pack................ .020" (.50 mm)

Required shim pack opposite ring gear...... .040" (1.02 mm)

(1) - Value from 1) above.

(2) - Value from 3) under "Side Bearing Prelaod"

Add a value of .002" (.51 mm) to each shim pack calculated above for preload

3) Stretch case specified amount and from calculations made above, select required shim pack. Install differential assembly in case with shim packs. Loosen case stretcher and remove. Install bearing caps as originally marked and tighten bolts. Rotate pinion to settle differential bearings and position dial indicator using suitable adapters to measure ring gear backlash. Measure backlash at several locations, it must be to specifications. If not, interchange shims from side to side to achieve specified backlash. NOTE - A movement of .002" (.05 mm) shim thickness from one bearing to the other will vary backlash by about .002" (.05 mm). Reinstall differential assembly in rear axle housing.