For:

- Toyota (1963-75)

- Honda (1963-75)=

DESCRIPTION

Toyota uses two types of regulators, a single element type and a two element type. Two element types consists of a voltage regulator and voltage relay. Single element type has a voltage regulator only.

APPLICATION

Engine Part No.

KC (1969-70)............................................. 22010

3K-C (1970-73).......................................... 22010

2T-C (1971-73).......................................... 22010

BR-C (1969-71).......................................... 33010

18R-C (1972-73)......................................... 33010

3R-B (1965-67)

1900 Sedan.............................................. 31011

Crown

Prior to Eng. 3R 479894........................ 40020

After Eng. 3R 479894............................ 40021

Corona

Prior to Eng. 3R 479894........................ 31010

After Eng. 3R 479894............................ 31011

3R-C (1968-70)

Prior to 10/68.......................................... 31011

After 10/68.............................................. 31010

M (1965-68)............................................... 40021

2M (1965-68)

Prior to 11-68.......................................... 41010

After 11/68.............................................. 41011

4M

1971-72................................................... 41012

1973........................................................ 33010

F (1965-73)

FJ 40 (1965-72)....................................... 40010

FJ 55 (1970-72)....................................... 33010

All 1973 Models....................................... 40011

Honda........................................................ 026002420

1975 Models

Toyota

F & 2F Engines

FJ40.................................................... 60080

FJ55.................................................... 36010

20R Engines

Hilux...................................................... 38050

All Others............................................... 38010

2TC Engine................................................ 38010

4M Engine

To Dec. 1974.......................................... 36010

From Dec. 1974...................................... 38010

Honda

Civic...................................................... 31400-634-671

"All part models start with 27700 prefix"

" Eng. numbers F224280 thru F279664 use part number 27700 40011

|

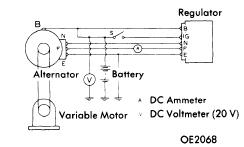

| SINGLE ELEMENT TYPE TEST CIRCUIT |

|

| TWO ELEMENT TYPE TEST CIRCUIT |

TESTING

VOLTAGE REGULATOR

Connect test meters to voltage regulator circuit as shown in illustrations. Vary alternator RPM and check voltmeter reading. Increase alternator RPM and check voltage when ammeter register 1/2 of maximum rated alternator output. Voltage should be 13.8 - 14.8 volts. Adjust alternator speed to 3,000 RPM, voltage output should again be 13.8 - 14.8 volts. If voltage is not within specified range, adjust voltage regulator by bending arm to obtain correct setting.

VOLTAGE RELAY

Charge Warning Lamp Type - Connect test, meters as shown in illustration. Increase alternator RPM gradually and note voltage when charge warning lamp goes out. Cut-n voltage should be 4.5 - 5.8 volts. If voltage is not as specified bend voltage relay adjusting arm to obtain correct setting.

Ammeter Type - Connect test meters as shown in illustration. Increase alternator RPM gradually and note voltage. Voltage should be 4.5 - 5.8 volts, if necessary, adjust voltage by bending adjusting arm.

ADJUSTMENT

NOTE - Adjustments are not applicable to sealed units. If points are slighly oxidized or pitted, dress contacts with suitable emery cloth (about 400 grit). If points are oxidized or pitted excessively, replace regulator assembly.

VOLTAGE RELAY

Contact Spring Deflection - Pres on armature and use a feeler gauge to check clearance between armature and point spring. Clearance should be .008 - .018" (.20 - 45 mm). Adjust by bending point holder "A" on relay unit.

|

| RELAY - WARNING LAMP TYPE TEST CIRCUIT |

|

| RELAY - AMMETER TYPE TEST CIRCUIT |

VOLTAGE REGULATOR

Armature Gap - Check with a feeler gauge, specified clearance is .024 - .032" (.6 - .8 mm), adjust by bending point holder "A".

|

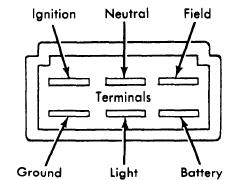

| TERMINAL POSITION FOR TWO ELEMENT TYPE REGULATOR WIRING CONNECTOR |

Point Gap - Specified point gap is .010 - .018" (.25-.45 mm). Adjust gap by bending spring holder "B".

Contact Spring Deflection - With armature depressed, check spring deflection with a feeler gauge. Specified deflection should be .008-.024" (.2-.6 mm). If deflection is not as specified, replace regulator assembly.

|

| TERMINAL POSITION FOR TWO ELEMENT REGULATOR WITH WARNING LAMP CIRCUIT |

Angle Gap - With armature depressed, check gap with a feeler gauge (see illustration). Specified gap is .008" (.20 mm).

|

| VOLTAGE RELAY |

|

| VOLTAGE REGULATOR |